Pro 2000-Fuel Gas is the result of mixing our Pro 2000-T concentrate with propane blends at a rate of 1:1000 gallons. Pro 2000-Fuel Gas is a reliable and economical fuel gas for cutting, heating and brazing operations. The performance of Pro 2000-Fuel Gas is comparable to acetylene yet safer with a high flow rate capacity. An added benefit to using Pro 2000-Fuel Gas comes from the material handling standpoint. A 100 lb. cylinder of Pro 2000-Fuel Gas has a volume of 866 cu.ft. while a standard acetylene cylinder contains 350 cu.ft. Translated into BTU’s, Pro 2000-Fuel Gas has 2,261,992 per cylinder while acetylene contains 518,000 per cylinder. Less cylinder change outs and more productivity.

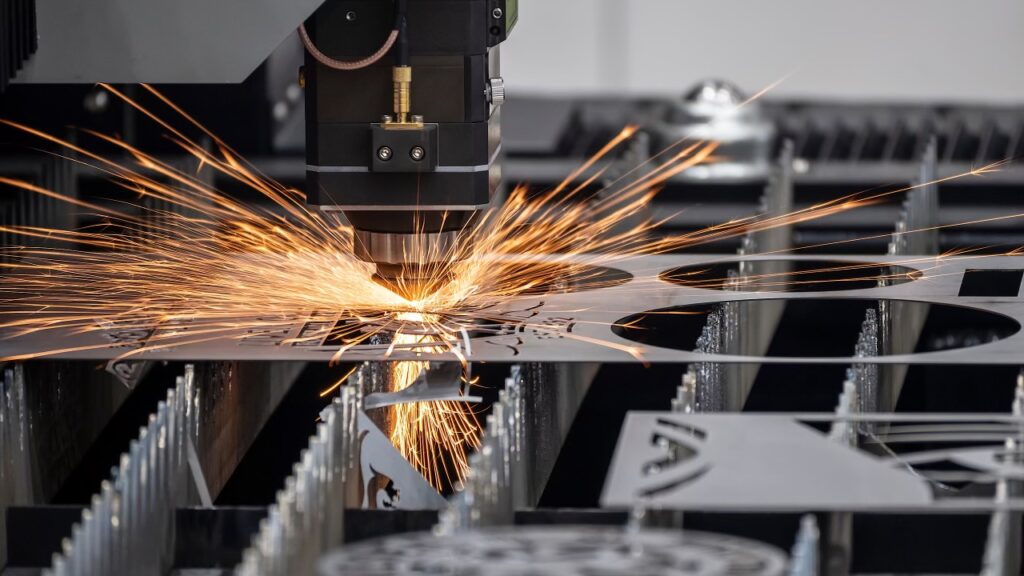

Pro 2000-Fuel Gas burns cleanly with no sooty black smoke. Pro 2000-Fuel Gas provides an extremely clean cut with virtually no slag or spatter. Little or no grinding is required after cutting with Pro 2000-Fuel Gas.

An enhanced LPG cutting fuel with a high heat value that produces fast starts and exceptionally clean cuts. An excellent choice for any shop that cuts, brazes, pre-heats or flame straitens carbon steel.

Pro 2000-Fuel Gas features

- High Withdrawal Rates

- Constant Composition

- Consistent Operating Results

- Fast Preheat Capability

- Uses Standard Two Piece Fuel Gas Tips

Pro 2000-Fuel Gas is safe to handle. It is not subject to detonation from shock. Pro 2000-Fuel Gas may be handled, stored and transported in standard D.O.T. approved LP Gas equipment. It will not form explosive acetylides when in contact with copper or silver alloys. Copper pipe or tubing may be used in distribution systems.

Benefits of using Pro 2000-Fuel Gas

- Fast starts – as fast as acetylene

- Clean cuts – cleaner than acetylene

- Faster Pre-Heating than acetylene

- Higher flame temperature than propane

- Lower fuel consumption than propane

- Start and maintain a high quality cut even on heavily rusted or mill scaled material.

What is needed to change over from Mapp, Propylene or propane to Pro 2000-Fuel Gas? Nothing! Use the same tips, torch, regulators and hose. When changing over from acetylene you need to change the cutting tips, rosebud and your twin hose assembly. Pro 2000-Fuel Gas will reduce your total costs and improve your cutting. In many cases eliminating the need to grind.

The best time to start improving your cuts and saving money is now. Contact us today to arrange for a demo in your shop. We can also do a computerized cost analysis so you can see just how much money you will save.

Who will benefit from using Pro 2000-Fuel Gas?

Virtually everyone who does Oxy–Fuel cutting, heating, brazing and flame straightening.

| Body shops | Plate shops |

| Canneries | Plywood mills |

| City works yards | Portable welders |

| Container repair | Pulp & Paper mills |

| Fabrication shops | Sawmills |

| Garages | Scrap cutters |

| Hobbyist | Shipyards ** |

| Maintenance shops | Truck and trailer repair shops |

Essentially any business that uses Oxy – Fuel in their shop!

We’ve converted customers who cut with propane, acetylene and other alternate fuel gases. All are pleased with the cut quality and cost savings.

When you change to Pro 2000-Fuel Gas your shop will save money, improve cut quality and enhance safety. Isn’t now the best time to start?

Pro 2000-Fuel Gas vs. The Competition

| Competitive Product | Pro 2000-Fuel Gas Advantage |

|---|---|

| Acetylene | A higher amount of btu’s per cylinder. 5.63 * times more volume per cylinder. One 45 kilo cylinder equals 3.25 ( 8.49 m3 ) cylinders of acetylene. A much safer product. It is not shock sensitive, has lower explosive limits in air and less tendency to flashback. Cylinders are lighter and easier to handle. About 1/3 the cylinder handling. The cuts are cleaner with little or no slag. Plus, a much lower product and total cost. |

| Propylene | Lower cost. Improved performance on rusty or heavily mill scaled plate. Quicker starts. |

| Mapp Gas | Much lower cost. Improved performance on rusty or heavily mill scaled plate. Quicker starts. Less tendency to flashback. |

| Propane | Greater amount of btu’s. Uses less Oxygen. Has a higher flame temperature. |

Pro 2000 Fuel Gas Myths

| Myth | Facts |

|---|---|

| It starts the cut too slow | Cuts starting from an edge start as fast as acetylene. It has to do with proper torch set-up. Pro 2000 Fuel Gas is slower on a pierce cut and you can’t get away from that. But you can diminish the effect by increasing the fuel flow by 2 or 3 psi. |

| You can’t cut thin material well | It cuts thin material very well. Just as with acetylene you must cant the torch over to about a 30-degree angle. Start your cut and move quickly. The problem with thin material with all gases is that it tends to fuse together after the cut. Pro 2000-Fuel Gas is superior on material over 1 1/2“. |

| They don’t like the long lazy pure fuel gas flame and complain that it blows out in the wind | I don’t like the long lazy pure fuel gas flame either. Learn to start the torch with both the Pro 2000-Fuel Gas and the oxygen on. It’s pretty impressive once you have mastered it. It gets away from the long lazy flame and starts immediately in the wind. It’s also an approved method by the AWS (American Welding Society) for starting a torch with this type of fuel. You can’t do this with acetylene as it may well lead to flashback. |

| It won’t cut rusty material | Just bring it on. Pro 2000-Fuel Gas cuts very heavily rusted material with ease and with a cleaner finish than acetylene. |